Introduction

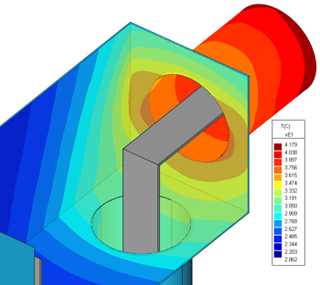

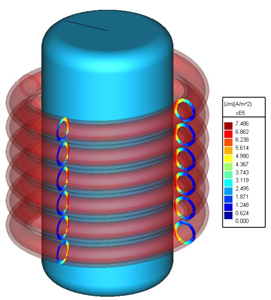

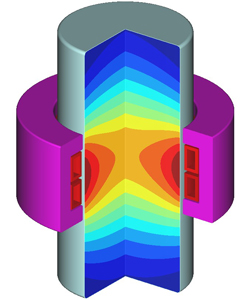

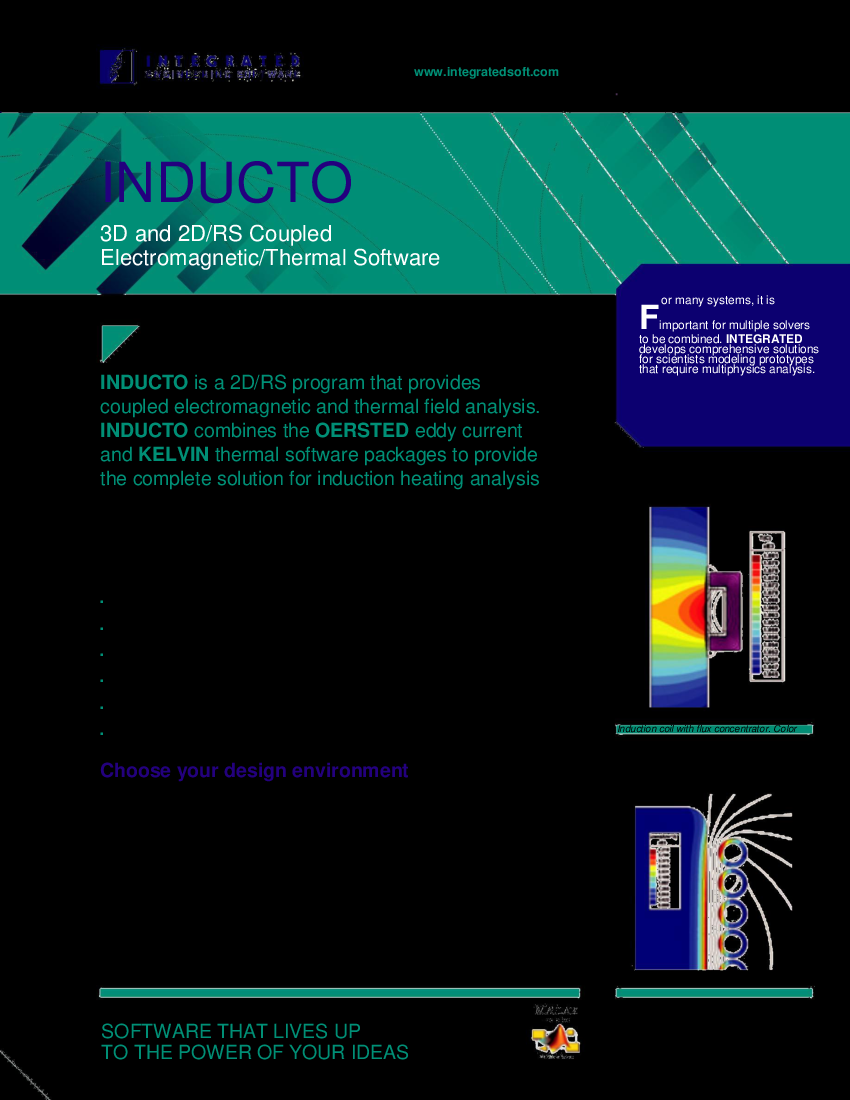

INDUCTO 3D™ program provides coupled electromagnetic and thermal analysis in the 3D domain. The eddy current simulation capabilities of FARADAY are linked to the thermal analysis capabilities of CELSIUS to provide a complete solution for induction heating problems.

INDUCTO 3D™ can perform both transient and steady-state simulations. In addition, the FARADAY™ and CELSIUS™ modules can be used separately when coupled simulations are not required.

Using INDUCTO 3D™ designers can:

- Determine temperature distribution at all points within a workpiece

- Calculate effective resistance and reactance of induction coils

- Calculate total power requirements for induction heating systems

- Custom design coils to accommodate specific induction heating applications

- Design flux concentrators, magnetic shunts and electromagnetic shields

- Investigate effects of transient heating and cooling regimes

Features

- 3D RF and microwave field solver for a diverse range of applications.

- Finite difference time domain solver.

-

At no extra cost, our software packages include:

- Choice of solvers: To ensure you have confidence in the solution and for independent verification, both BEM and FEM methods are included in the same software package to suit your specific application needs. Not every solver fits every application, no “one size fits all”.

- Choice of optimization tools: Parametric Analysis for those who need fast and easy optimization with a short learning curve. API and Scripting give more power to advanced users. Both tools are available in the same package.

- Built-in material libraries:Customize and create your own library for easy access to the materials you use.

- Integration with MATLAB®: Users' MATLAB code can include function calls to the INTEGRATED API to build geometry, assign physical parameters, solve, and obtain results.

- Parallelization: When used on 64-bit computers, this permits full utilization of the available RAM to dramatically increase speed of solution and post-processing.

- Intuitive interface that can be easily customized according to user preferences (overall appearance, toolbars, solvers, backgrounds, defaults, etc.)

Technical Papers:

Dr. Ricardo Castro Lopes

R&D Director

Efacec Energia, Portugal

“At EFACEC, innovation is in our DNA. For over 26 years, we’ve trusted INTEGRATED Engineering Software to transform our design process. The powerful suite—including ELECTRO, FARADAY, INDUCTO 3D, and COULOMB—has enabled our team to build precise virtual prototypes, fine-tune critical parameters, and eliminate costly errors before production begins. Their bespoke Partial Inception dialog feature, developed in response to our unique challenges with transformer insulation design, has been a game-changer. It empowers us to simulate dielectric tests and validate our designs with unparalleled accuracy, ensuring each transformer meets our rigorous standards. With INTEGRATED’s flexible and advanced simulation tools, we not only accelerate our design lifecycle but also maintain a competitive edge in a rapidly evolving market.”

John Hauck

Principal Research Scientist,

Endocardial Solutions, USA

“INTEGRATED has impressed me with their willingness to work with the customer to solve unique problems.”

Yueqiu M. Unamck, P.E.

Mechanical Engineer,

Resodyn Corporation, USA

“Thank you very much for your quick response and help. I realized my mistake and my program is working now.”

Andrew Hilton, M Eng.

The University of Nottingham, United Kingdom

“I once again extend my thanks for your help on this matter. It is more than I have come to expect from a lot of companies.”