-

- Actuators

- Coil Design

- Electromagnetic Brakes & Clutches

- Inductors

- Levitators

- MRI

- Motors

- Alternators and Generators

- Electromagnetic Brakes and Clutches

- Sensors

- Loudspeakers

- Magnetic Encoding

- Relays and Contactors

- Solenoids

- Shielding

- Electromagnets

- Magnetic Bearings

- Magnetic Signatures

- Magnetic Fixtures

- Magnets

- Non Destructive Testing

- Particles

-

- Antenna Radiation Characteristics

- Simulation of an Airplane

- EM Simulation of a Desktop

- EM Compatability and EM Interference

- Cable Junctions and Terminations

- Filters

- Lightning Strikes

- Microwave Circuits

- Microwave Ovens

- MRI

- Near Field Analysis

- Radar Cross Sections

- Radio Frequency Cavities

- Reflector Antennas

- Sensors

- Ultra Wideband Antennas

- Waveguides

- Antennas

Variable Speed Drives

Optimizing the efficiency in variable speed drives can offer some impressive energy savings: the energy saving potential can go up to 10% for high efficiency motors, 30% by using frequency converters and an astonishing 60% by optimizing the entire drive train, according to the German Electrical and Electronic Manufacturers’ Association, ZVEI (Source: “Energiesparen mit elektrischen Antrieben”, ZVEI Broschüre, April 2006).

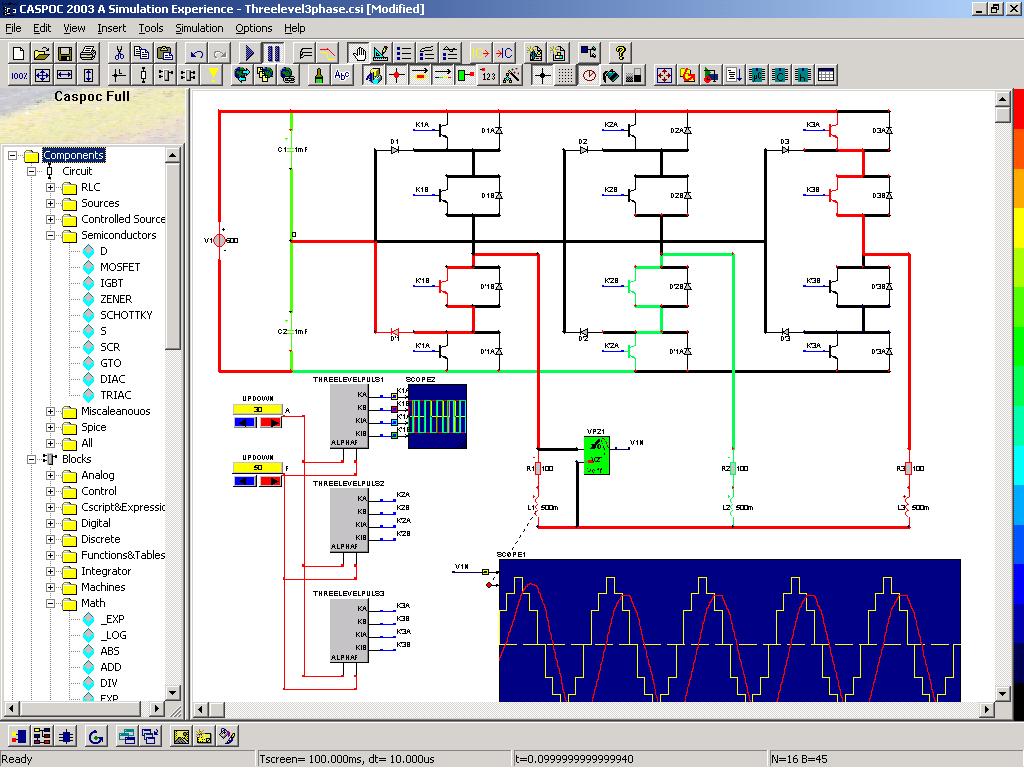

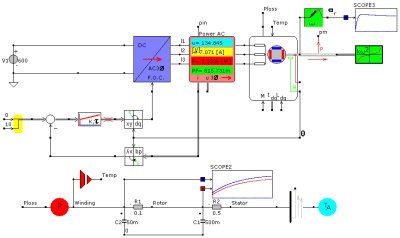

By using FEM, the losses in high efficiency motors (like induction machines and permanent magnet synchronous machines) can be minimized. CASPOC™ imports the model including the information on the efficiency of the motor. The program simulates the efficiency of the entire variable speed drive depending on various operation conditions.

CASPOC™ allows the simulation of the entire drive train including the inverter, control and mechanical load, so efficiency and controllability can be optimized. For various load conditions, losses in the power electronics and the electrical machine can now be minimized, so your products comply with the new international efficiency classes IE2 and IE3.